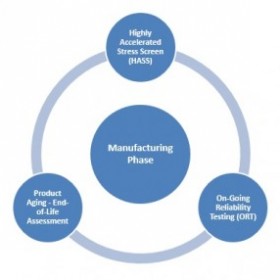

Any product and even well designed ones could experience high rate of early life failures. This could be attributed by the variability in the manufacturing process like solder joints or components. HASS is an accelerated production level screen test that is based on the HALT methodology and can reveal latent flaws not detected by the standard environmental stress screening or burn-in. The goal is to find the marginal types of defects that are in the category of infant mortality and manufacturing failures. The FMECA results can be helpful in identifying the proper screen for the product.

- Highly Accelerated Stress Screening Plan

- HASS execution which includes testing, monitoring and the final report

- On-Going Reliability Test Plan

- ORT execution which includes testing, monitoring and the final report